How are we different?

Benefits of SilverJack

Benefits of SilverJack

SilverJack built-in optimization capabilities allow for the freedom to quickly respond to changing flow dynamics without expensive and labour-intensive manual processes. The result is an intelligent artificial lift system that maintains peak efficiency while increasing production and decreasing downtime.

Enhanced Well Head Equipment

Technology

Precision control with hydraulic cylinders

- sensor bar for position monitoring

- purpose built, integrated optimization controller

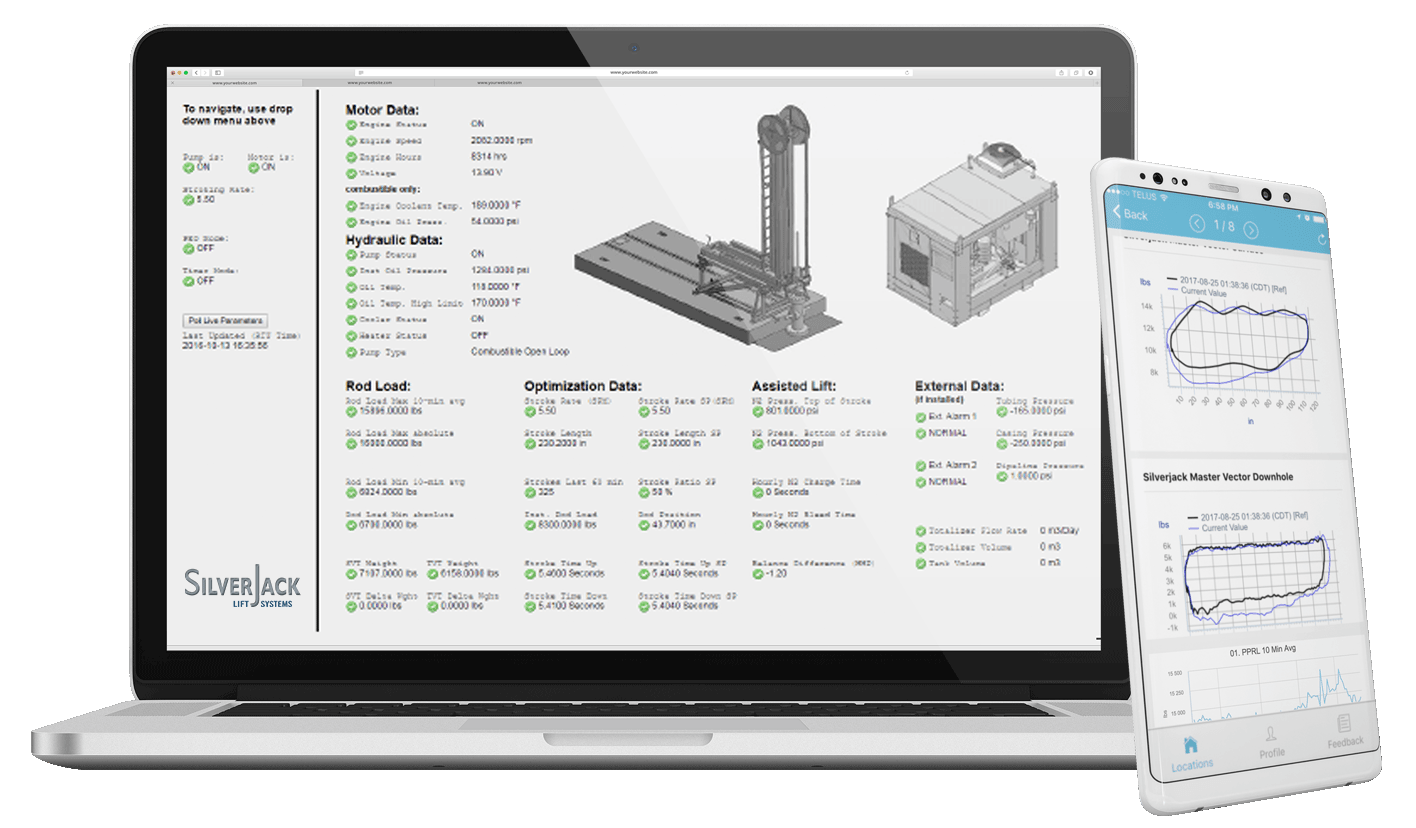

24/7 monitoring from anywhere

Web Enabled

SilverJack IS supported by SCADA Access

- Remote surveillance and control

- Long term data trending for alarming and troubleshooting

- Smartphone App for mobile user convenience

Best in class

Optimization

Purpose built optimization controller, SCADA Access web host, hydraulically driven pumping unit all combine to provide best in class optimization capabilities

- User Initiated Optimization

- Autonomous Optimization

- Focus on issue resolution not just issue identification

WHAT IS SILVERJACK BUILT FOR

Application

Quick detection and unique resolution to pumping problems. SilverJack is fully capable with gas driven systems offering full optimization

Long stroke application (300")

High Production Rod Pumping

- Transition from ESP's or gas lift to rod pumping

- Deviated wells, slower stroke can move higher volume with less wear

- Better performance with higher GOR (higher compression ratio)

- Wear distribution on rod string and tubing will maximize system life

Issue Identification & Resolution

Challenging Rod Pumping Applications

- Fully featured controller integrated with remote access web host provides unparalleled visibility into pump status and performance

- Leverage flexibility of hydraulics to change any portion of pump stroke profile

auto adjust with Declining Wells

High Decline Rates

- Remotely change stroke rate/length. No mechanical changes, site visits or downtime.

- Eliminate need for counterweight changes as well pumps off

- Eliminate gear box loading issues as well characteristics change

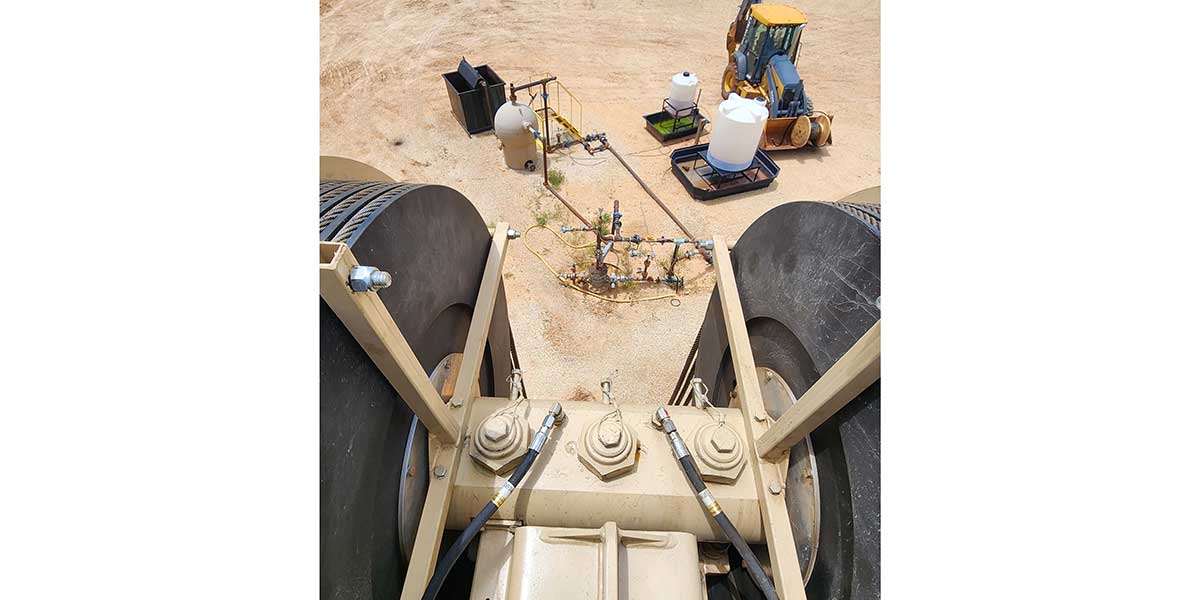

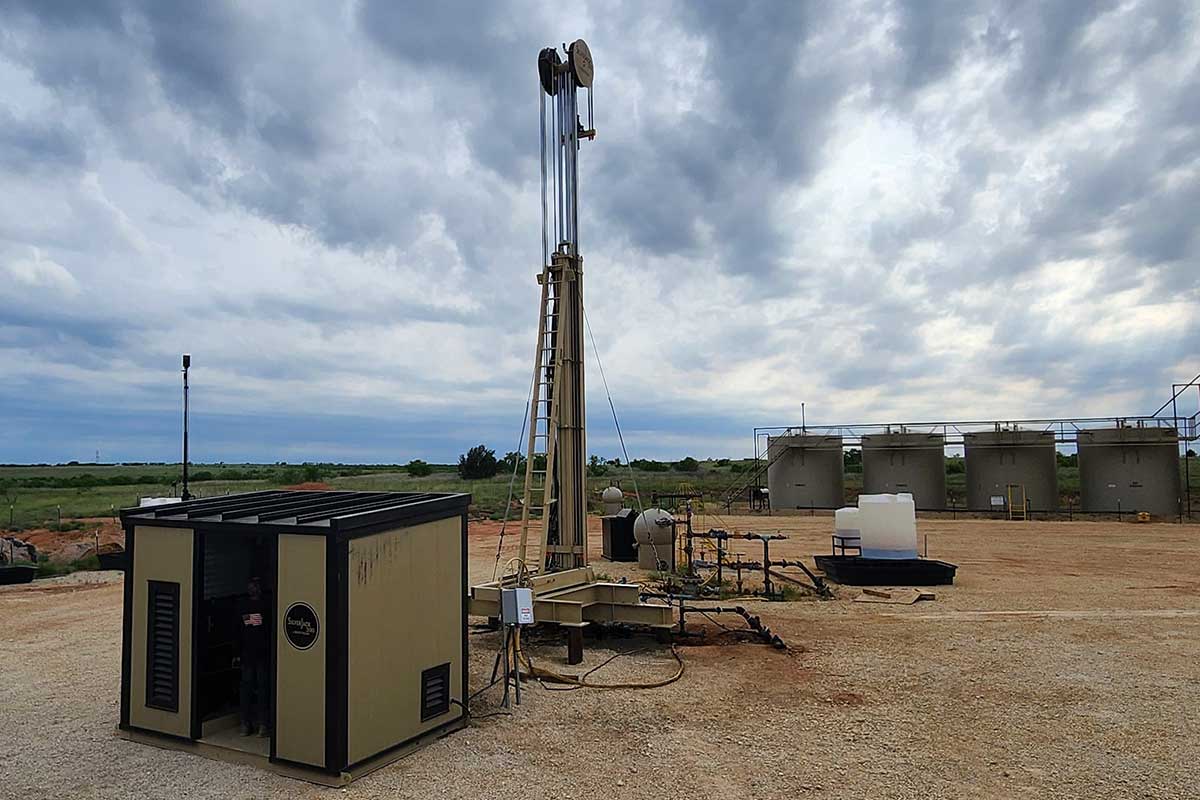

Land owner challenged installations

Space Constrained

- Multi-well pads with tight well spacing

- Safety advantages in more populated areas

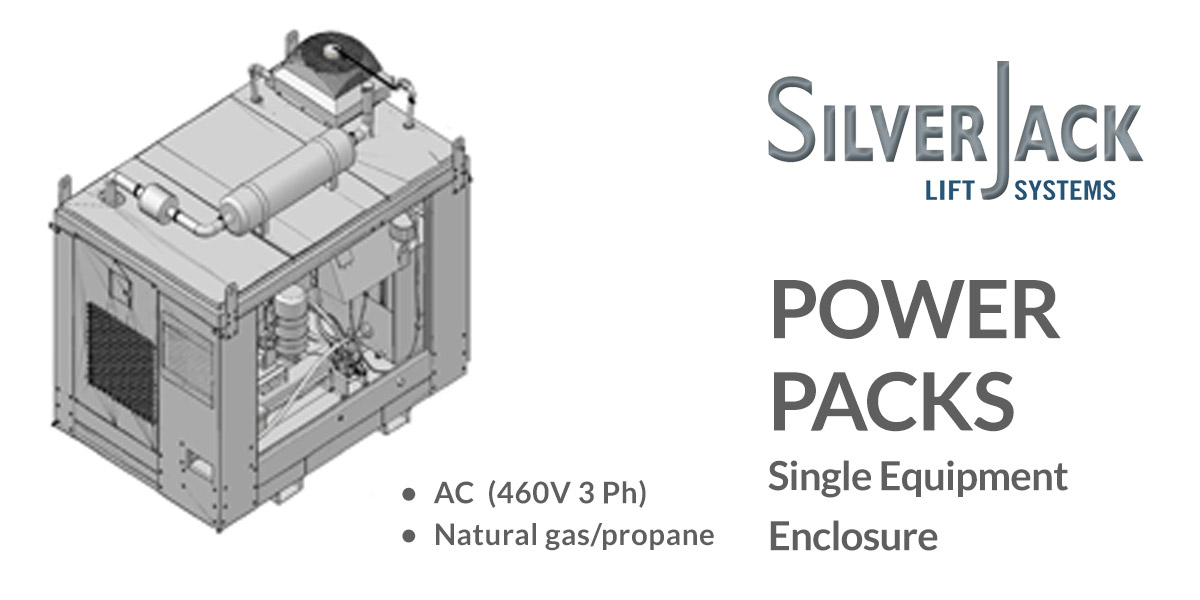

Two pumping models

Our Products

We offer two models of the SilverJack Lift Systems – SJ150 & SJ300. Find out which one will work best for your application.

Pump model

SJ150

Pump model

SJ300

LONG STROKE

< 250 bbl/day

(< 40m3/day)

- Up to 29,000lb peak polish rod load

- Up to 150" max stroke lengths

- Direct well head mount

- Small footprint. Install in confined spaces

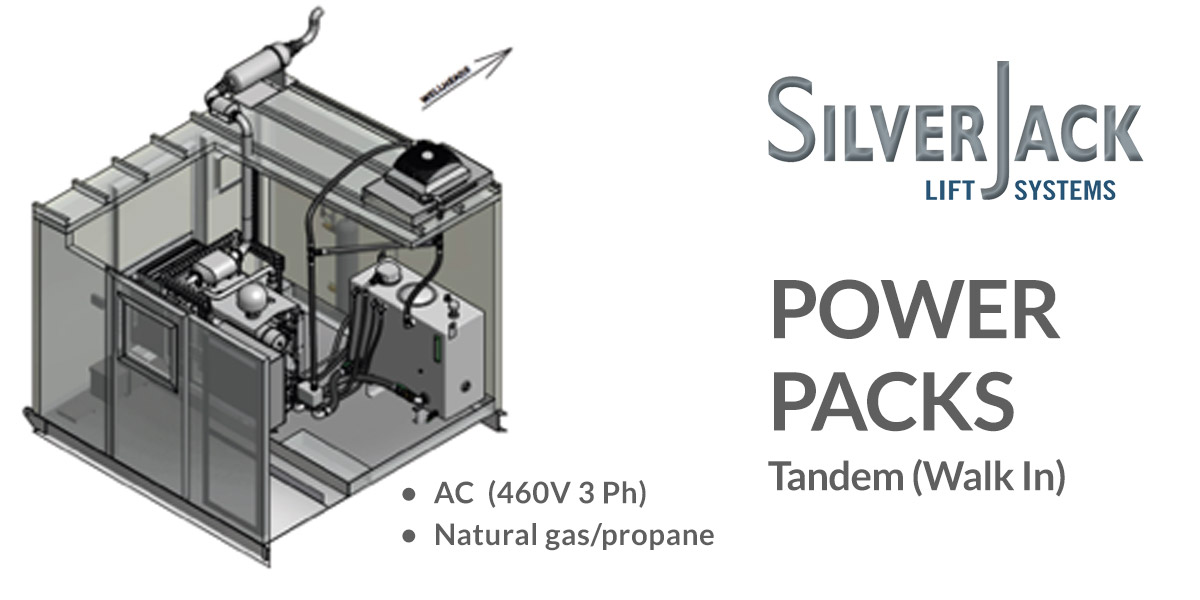

- AC & natural gas/propane powerpacks with various configurations

- Single Equipment Enclosure

- Tandem (Walk-in)

<1,250+ bbl/day

<200m3/day

- up to 50,000 lbs polish rod load

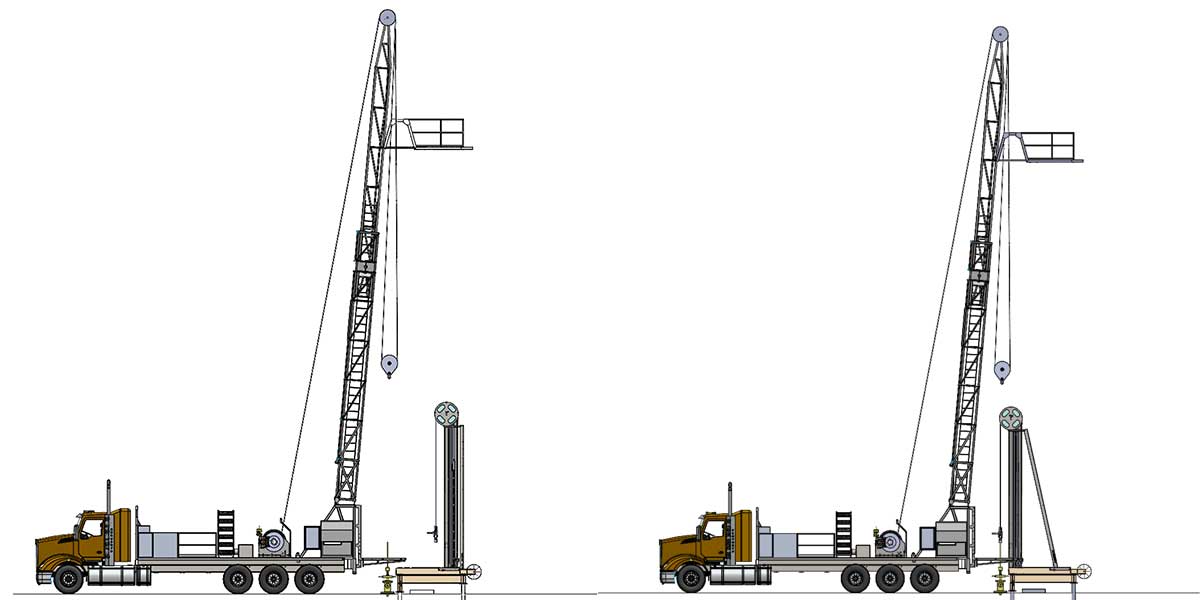

- up to 300" long stroke length

- Solid and secure base structure

- AC powerpacks. Full enclosure configuration

- AI adjusting N2 Lift Assist

- Utilizing a bridal system for polish pod attachment point and external stuffing box.

- Anchored cable and pulley system 1 to 2 movement ratio

- 300" stroke length only requires ~150" cylinder length

SJ150 & SJ300

Key Differences

- SJ150 150”

- SJ300 up to 300”

- Design uses cables to attach to rod string (external stuffing box)

- Cables run over pulleys on the cylinder ram

- With moving pulleys, each 1” of cylinder movement results in 2” of rod string movement

- 300” stroke length only requires ~150” cylinder length

New Changes

Quality Improvements

Less Connections preventing spills and lost N2

- 8 Cable Design with Improved Material

- Changed from a 4-cable design to an 8-cable design to make sheaves and cables last longer

- Half Moon Removed

- Removing failure point and replacing with robust system with backup nuts

- Aluminum Bronze Gland

- The gland material is aluminum bronze rather than steel that could potentially rust and cause contamination

- Welded Port Removed

- The welded port is gone on cylinders reducing wait time on parts.

Safety & Service

Rig Servicing Improvements

Fastest and Safest Equipment to Rig-In/out

- Perfect Alignment

- Pile design allows perfect alignment –Customers have seen 50% reduction in maintenance costs over concrete base.

- Slide Mechanism

- During well servicing, unit has proper slide mechanism that allows one person to remove 6 bolts and slide unit back in less than 5 minutes.

- No Hoses Get Disconnected During Servicing

- Reduced Footprint

- Even though the unit has longer stroke it has lower footprint.

- Stability

- The ladder acts as stabilizer for any motion and makes unit more rigid.

- Clutter Free Tubing

- The structural design allows tubing to be stood in tubing board with no obstacles.

THE POWER OF SILVERJACK & SCADA ACCESS

Optimization

MEASURE

ANALYZE

OPTIMIZE

TEST

Reduce Time to Complete Optimization Cycle

LIVE OPERATIONAL DATA • ALARMING

• REMOTE SURVELLIANCE • CONTROL CAPABILITIES

Scroll down for examples of scenarios with resolutions

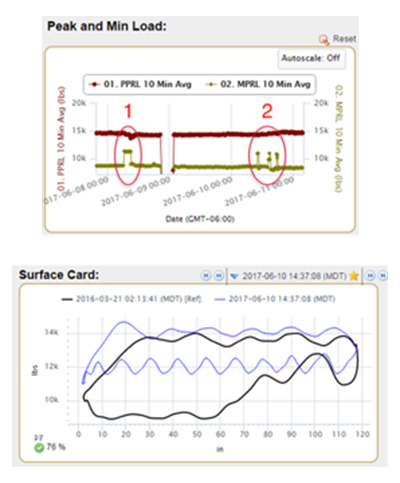

SCenario #1:

Standing Valve

Stuck Open

MEASURE

- Downloading polish rod loads every 15 minutes

ANALYZE

- Alarm set on MPRL trend: High MPRL alarm sent

- Alarm triggers user to investigate (manage by exception)

- User connects to remote access web host to investigate and determine problem

30 - 40 min

Problem Resolution/Confirmation

OPTIMIZE

- User remotely increases down stoke speed via SCADA Access

- Increases fluid velocity passing open valve to flush debris

TEST

- Monitor data trends on SCADA Access to determine if problem is resolved or further action required.

SCENaRIO #2

Gas Lock

MEASURE

- Downloading polish rod loads every 15 minutes

ANALYZE

- Alarm set on pumpfill drop

- Alarm triggers user to investigate (manage by exception)

- User connects to SCADA Access to investigate and determine problem

Gas Lock Intervention

Supported by Autonomous Optimization

OPTIMIZE

- User remotely increases down stoke speed via SCADA Access

- If faster down stroke not successful, lower bottom position to put well on tap. History shows 50-70% success rate.

TEST

- Monitor data trends on SCADA Access to determine if problem is resolved or further action required.

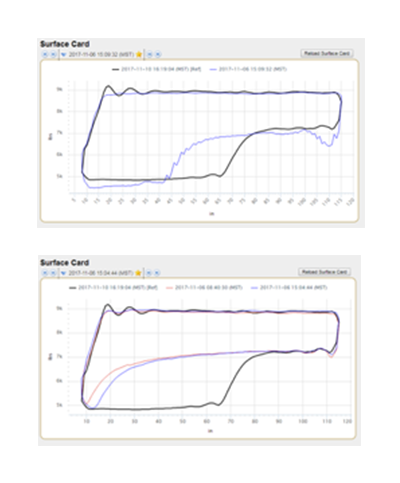

SCENARIO #3

Hole In Tubing

MEASURE

- Downloading polish rod loads every 15 minutes

ANALYZE

- Alarm set on PPRL trend – Low PPRL alarm created

- Alarm triggers user to investigate (manage by exception)

- User connects to SCADA Access to investigate and determine problem

OPTIMIZE

- Mechanical issue that cannot be resolved with Optimization

- Value is in early notification and problem identification

Minimized troubleshooting time & cost

Identified problem remotely in 1hr

with no field testing.

TEST

- Reported Problem: Initial report was dropping production. No obvious problem. No visible change in PPRL.

- Troubleshooting Steps:

- Remotely reduced stroke rate, 5 SPM to 1 SPM,

- Demand polled pump cards,

- Overlaid pump cards to compare.

- Conclusion: At 1 SPM, PPRL slowly dropping (fluid escaping through hole exceeded amount being lifted). Column of fluid dropping. No surface production.

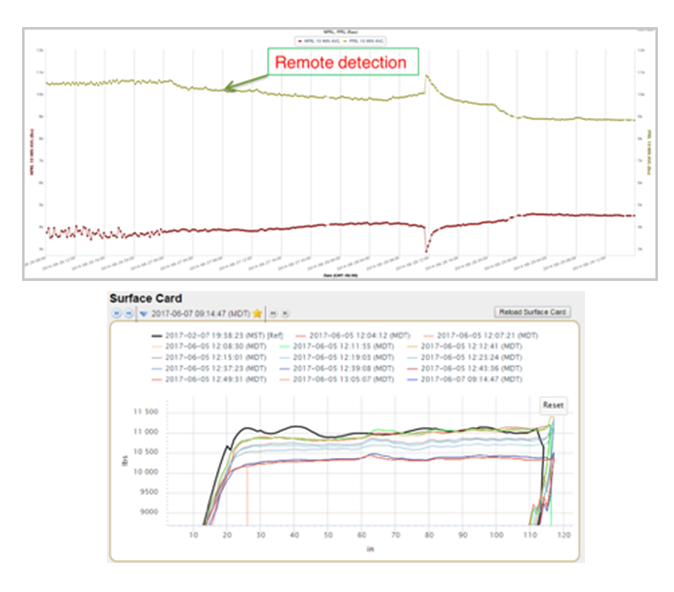

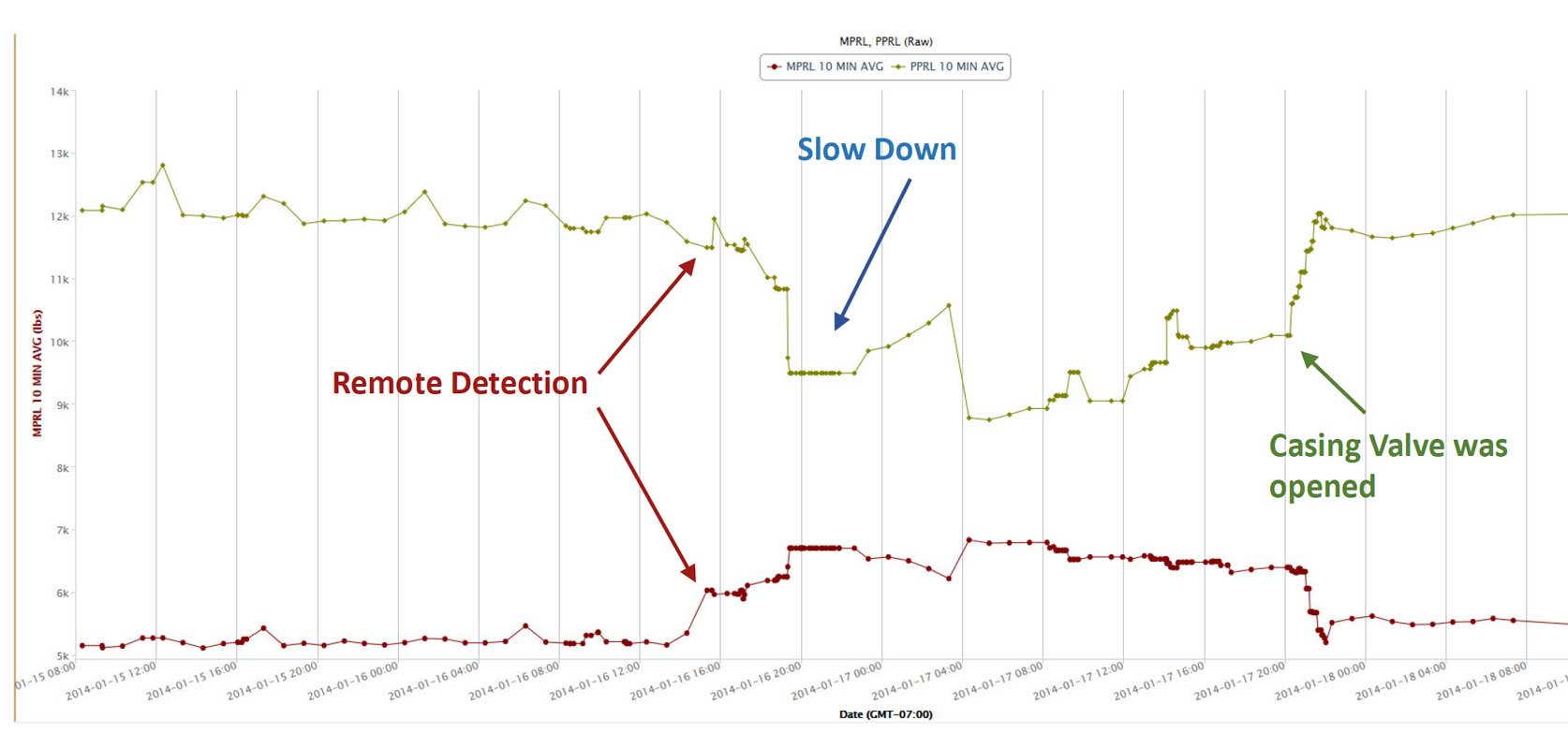

SCENaRIO #4

Casing Valve Closed

ANALYZE

-

Quick, significant drop in pump fill and upstroke rod load, increase in downstroke rod load.

-

Detected via rod load alarm.

Benefit

Quick detection avoided lost production

CONCLUSION

- Casing valve closed

SOLUTION

- Travel to site and open casing valve

product Division of TCB Manufacturing

Proven Designs. Proven Reliability.

Send Us a Message!

Contact Information

Box 549, Brooks, AB

T1R 1B5

1-877-361-4363

TCB Manufacturing

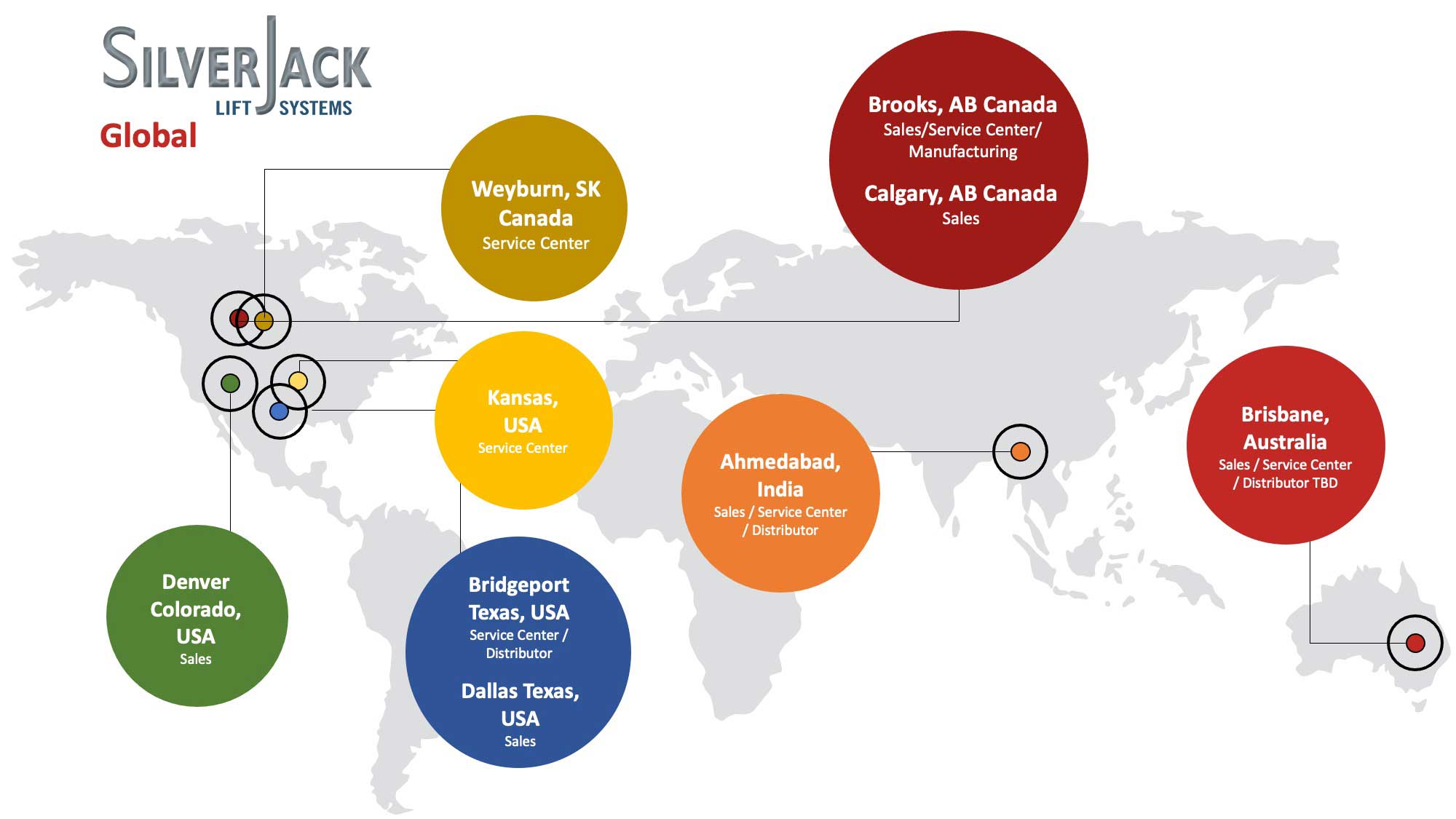

SilverJack Lift Systems Global Locations